Cryo-blasting

How it Works

Key Benefits

The non-abrasive nature of cryo-blasting makes it the only safe choice for the cleaning of ornate stone and architectural features in historical/heritage buildings, it is also the only safe method for soot removal from asbestos containing materials, as the dry ice never actually touches the surface of the ACM

Cryo-blasting is as powerful as solvent cleaning BUT has less environmental impact when used to remove dirt, soot and smoke odour

Since cryo-blasting is non-conductive it is used to remove contaminants from delicate electrical equipment; all surfaces remain completely dry throughout the process and downtime for production equipment is

drastically reduced

drastically reduced

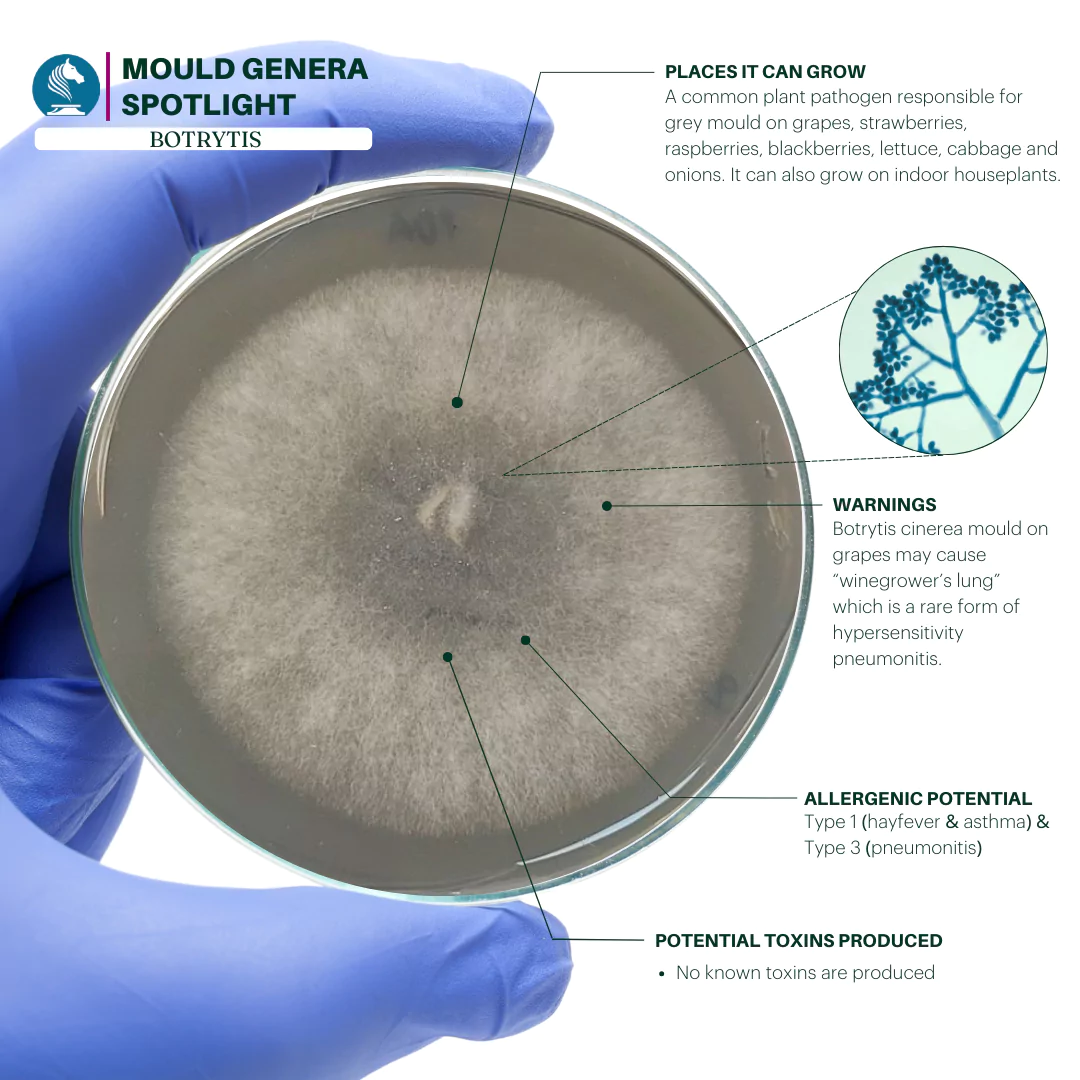

Mould remediation can now be 100% successful, as cryo-blasting reduces the surface temperature to -79C and all microbial growth is destroyed

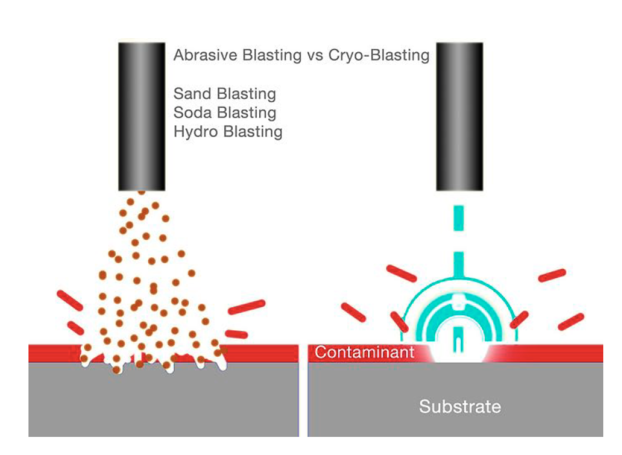

Cryo-blasting creates a micro thermal shock that breaks down the bond between the contaminant layer and the substrate. High pressure air then removes the contaminants as the media sublimates to carbon dioxide

Applications

- Fire Damage Restoration on Bricks / Wood

- Mould Remediation

- Historic / Heritage Buildings

- ACM decontamination

- Graffiti Removal

- Electrical Equipment

- Food / Drink / Print / Production Equipment

- Hospitals / Public Buildings

- Hotels / Restaurant Equipment