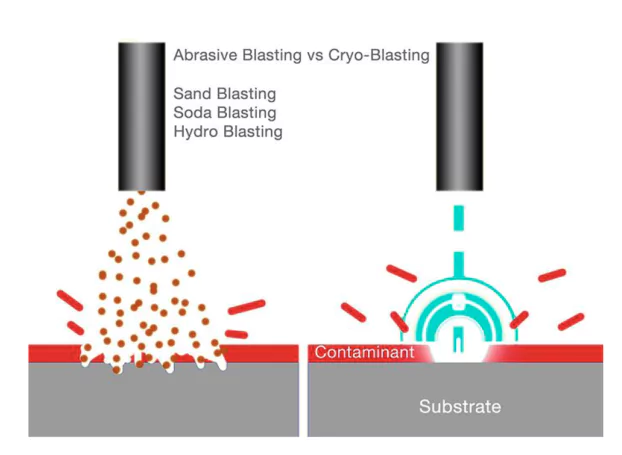

Dry Ice blasting – market leading, environmentally safe fire damage restoration. Removes soot, dirt and contamination from buildings and production equipment without any substrate damage

Chemical free, leaves no residue, removes harmful deposits without water, protects underlying substrates

Dry ice blasting can benefit both commercial businesses and clients in multiple ways:

As an environmental and sustainability focused business; we have sought to use the most effective methods to restore buildings, equipment and personal property with the least impact on our environment. Our investment in new innovative technologies has helped us to achieve our goals in minimising our use of harmful chemicals.