Following a referral by one of our supply partners, WHITE KNIGHT were very pleased to engage with an artisan brewery firm in the south of England this Spring (2023) to perform a mould decontamination on one of their rural brewing barns.

Brewery Barn Overview

Another disaster restoration firm had attended the barn previously to perform mould removal / cleaning works, however, just a couple of months later, mould proliferation had returned. The level of contamination that had returned was surprising given that a professional firm had been appointed previously to address and remove the mould.

It is clear that the mould removal protocol employed was inadequate and the cleaning solutions and methods used may have even accelerated mould proliferation. These findings clearly demonstrate the need for individuals and other organisations to seek out and engage with mould decontamination specialists when faced with such issues.

The first stage of the project was for WHITE KNIGHT to complete an Environmental Survey of the barn, which gives an accurate appraisal of the internal environment and therefore gives evidence to understand the root causes of the mould issues. To understand the conditions within the barn, WHITE KNIGHT used a variety of sampling and testing methods including:

Psychrometric Testing using a Protimeter MMS2, to record; indoor temperature, relative humidity, condensation levels and specific humidity – this testing showed that there was significant condensation on all surfaces within the barn, pointing to this being a main contributing factor to the mould growth.

IAQ (Indoor Air Quality) Particulate Analysis – for IAQ testing, WHITE KNIGHT predominantly uses the Trotec PC200 particle counter, to analyse the presence of particles of various sizes. Mould spores and hyphal fragments are typically found in the range of 3-20μ (microns). The 5μ levels recorded on-site ranged from PM 3 to PM 8, which was well below the target goal of PM 829, indicating very low levels of mould, pollen, dust, fibres and debris in the air. The readings showed that the indoor air quality within the barn was not of concern and was well within acceptable limits.

ATP (Adenosine Triphosphate) Analysis – this testing method uses a sterile test swab and Hygiena Ensure luminometer to create a system to confirm the hygienic status of surfaces by measuring ATP, the universal energy molecule found in all animal, plant, bacterial, yeast and mould cells. The ATP testing performed on this project showed excessive levels of contamination from living organisms – the level of microbial activity identified, highlighted a requirement for further laboratory analysis to determine the potential health risk level.

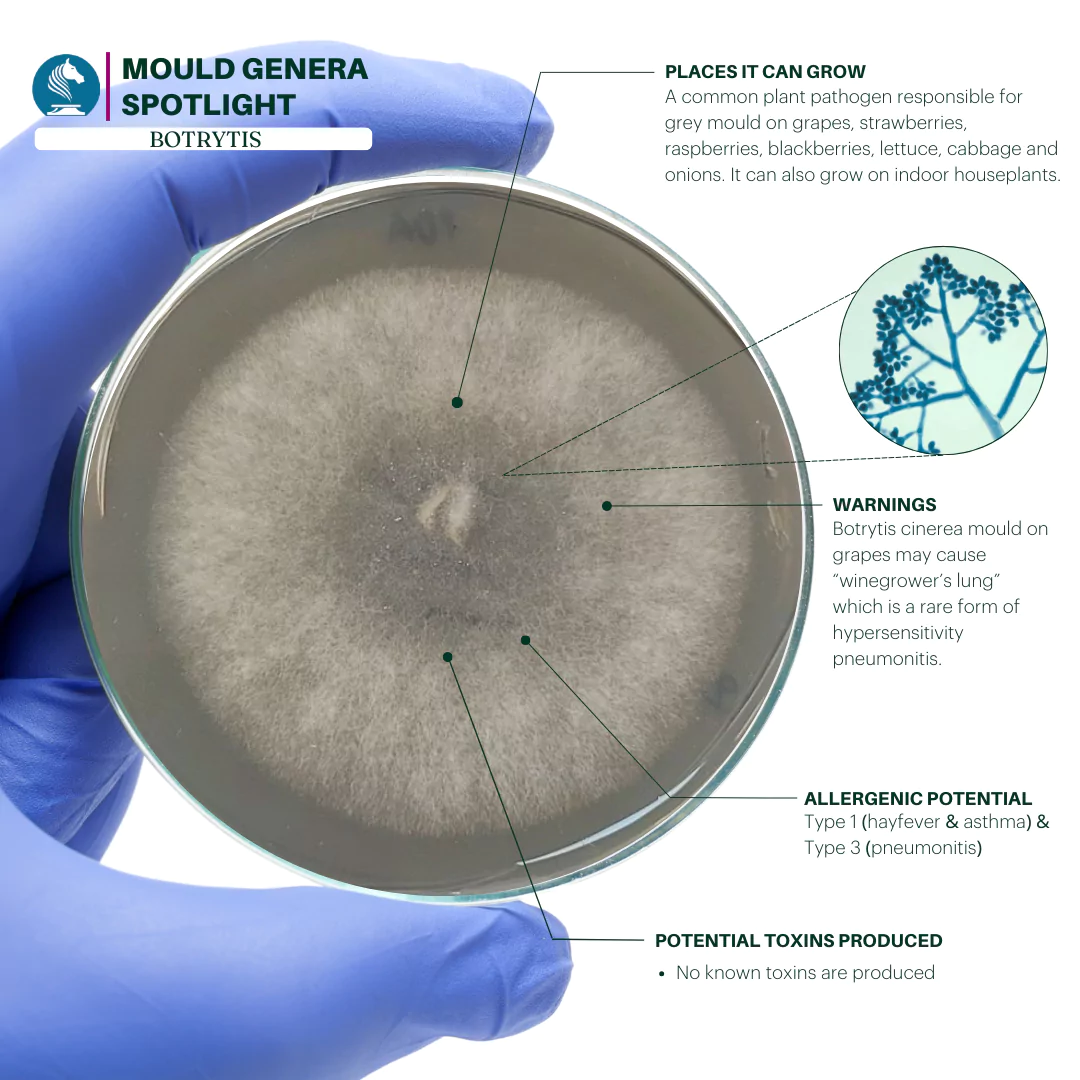

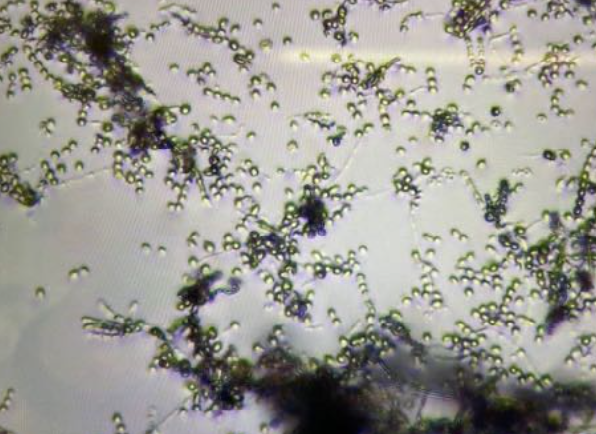

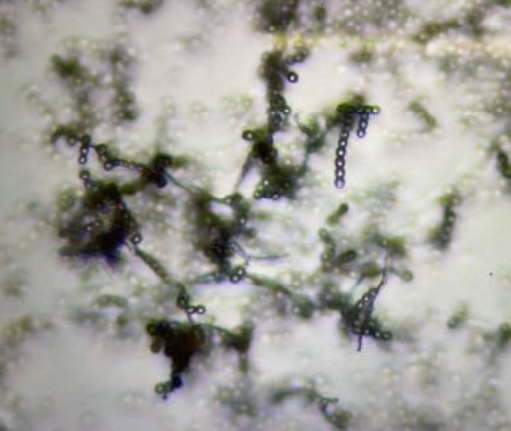

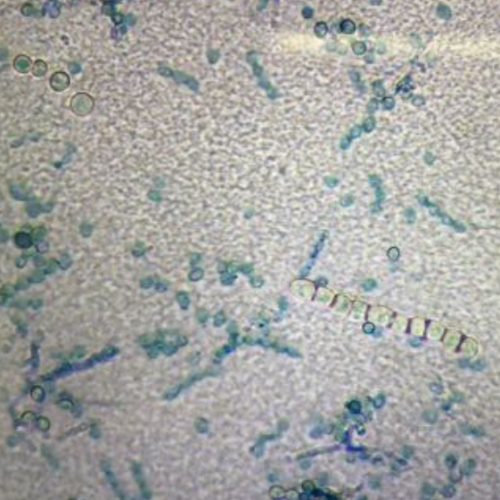

DMA Microscopy Analysis: Bio-Tape – for bio-tape lift samples, WHITE KNIGHT conducts analysis to ASTM D7658-17 ‘Standard Test Method for Direct Microscopy of Fungal Structures from Tape’. The results from the DMA laboratory analysis on this project identified high concentrations of mould spores in general, and high levels of dust and pollen particulates, that are consistent with the visible mould identified and general conditions in the affected areas. High concentrations of “marker spores” were present and indicated the need for urgent remedial action. The below images show the mould species identified from the tape lift samples, under the microscope:

Mould on Steel Frame

Mould on Beer Barrel

Penicillium

Aspergillus Flavus

Aspergillus Niger

Cladosporium

After submitting the technical report to the client and agreeing the recommendations, scope of works and quotation, WHITE KNIGHT were engaged to undertake the mould decontamination works.

The WHITE KNIGHT mould decontamination protocol is based on extensive research and scientific testing, and has been refined over a number of years, providing us with a market leading process. The protocol for the brewery barn was made up of a number of steps and considerations as follows:

Set up HEPA negative pressure units (NPUs) and engineering controls to create a vacuum chamber to remove as many spores as possible from the air as they are disturbed during the decontamination process

Remove all visible mould (to the structural components only i.e. walls, floors, ceilings and fixtures) with dry ice cryo-blasting

HEPA vacuum all wooden beer barrels with H-Class 3 stage filtration vacuum cleaners

Treat all affected surfaces with OXID-8 food safe anti-microbial certified to BS EN:1276. Apply by direct spray to the structure and onto microfibre cloths for the decontamination of the wooden beer barrels

Wipe clean all surfaces

Treat all surfaces with B-RINSE to remove all remnants of mould spores and hyphae and leave a light coating of borax crystals to assist in future mould control

Remove all NPU’s and seal the building for an application of SteraMist (our state-of-the-art decon misting system), to treat all surfaces and the indoor air, eliminating all pathogens and mVOC’s (microbial volatile organic compounds)

Allow barn structure to air out for 15-30 mins

Remove all engineering controls (protective sheeting / decon chambers)

Perform IAQ (indoor air quality) testing throughout the process

Confirm with Spore Trap Laboratory clearance testing that all contaminants have been removed from the environment

Upon successful completion of works, issue a decontamination certificate

Beer Barrel – Before Decon

Beer Barrel – After Decor

After undertaking the mould decontamination protocol outlined above, the relevant clearance testing was completed, and confirmed that the project was a success, with all key testing coming back and showing that levels were well within the acceptable limits. To aid with the condensation issue that had been identified, the brewery had already had a large ventilation fan installed into the structure which was helping to control the moisture levels, ensuring that condensation was being kept under control.

State-of-the-Art SteraMist Decontamination

If you have any queries regarding this project or if you have any mould or other decontamination needs then please do not hesitate to contact the WHITE KNIGHT team at helpdesk@wksg.co.uk or on 01536 682 300.